Cluster Tool Simulation Group

George Mason University

Problem

In implant tools, the interactions between the gases, and the plasma, affect the state and life of the ion source, which is the main component needed for the implantation process. Certain gases, such as Boron (B), deposit or grow layers of substances on the surface of the cathode; other gases, such as Arsenic (Ar), Phosphorous (P), Carbon (C), and Germanium (Ge), tend to erode the surface of the cathode, making it thinner. Thus, running a process with the same element for too long may lead to failure of the ion source.

If the cathode of the source component becomes too thin, the plasma may have direct contact with the source’s filament, leading to source failure. Similarly, if there is too much build up on the surface of the source’s cathode, the uniformity of the ion beam is deteriorated, leading to defects on the implanted wafer. On both situations, the source needs to be replaced, which introduces delays between implantations.

Current recipe sequencing does not take source deterioration into account, resulting in:

- Short and unpredictable source life

- Frequent and costly source changes

- Extended set-up times from instability

- Potentially less than optimal throughput

- Lost productivity due to reduced tool availability

Therefore, there is a need for a tool to aid in the scheduling of lots to extend implant tool availability and increase throughput

Scope

We were asked by our sponsor to model the behavior of a single implant tool with ion source deterioration to help them improve the scheduling for implant tools

Objectives

The expected outcomes of this project were the:

- Application of a systems engineering approach to cluster tool modeling

- Development of an executable model that can simulate an implant tool with ion source deterioration

Approach

The Cluster Tool Analysis Group designed a simulation tool for one implant tool with ion source deterioration in order to help improve the development of schedules. The resulting schedule improvements can help increase tool availability and reduce repair costs due to ion source failures, which is a main concern for our stakeholders.

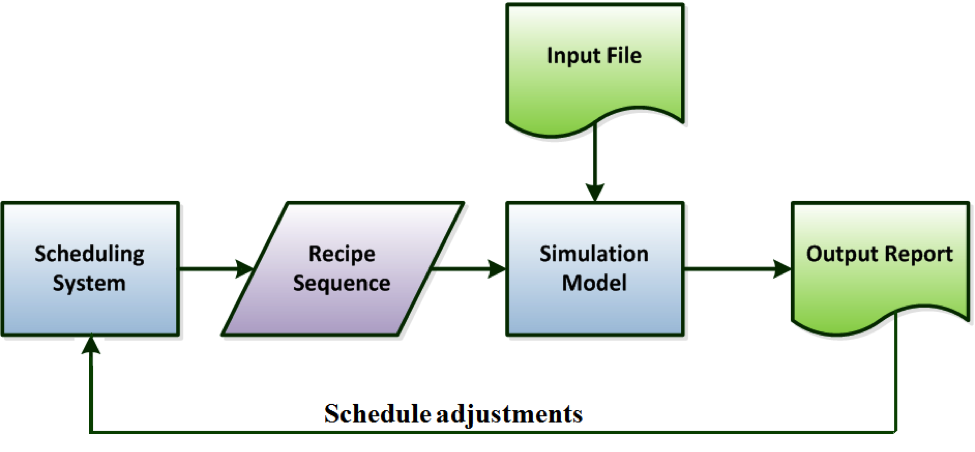

Our tool models the behavior of an implant tool and can take user defined deterioration effects, which the user can obtain from historical failure data from their implant tools. The simulation tool takes two inputs: implant process data, such as recipe times, set-up times, and the deterioration effect due to each recipe type; and a recipe sequence to be tested. This recipe sequence comes from a scheduling system, such as a scheduling algorithm. The output of the simulation system is a report containing information about the lots (groups of wafers) that were processed: the processing times, and the status of the ion source. A picture depicting our simulation model and its inputs is presented below.